How to Make Almost* Anything | MAS.863

Ella Peinovich | M.Arch Level III, MIT

Ella Peinovich | M.Arch Level III, MIT

3D Printer

For this week, I modeled a new and improved wall module shape that was comprised of a solid wall module with a more seemless transition between from the circular arm to the concave arm. Compared to the model I used to generate the G-code for the NC mill, this model for the 3D printer needed to be a closed volume, and thus much more precise.

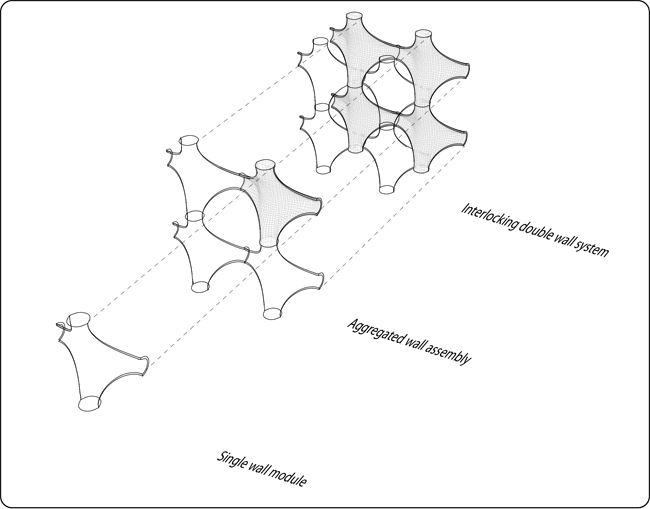

For the printing exercise I wanted to test the independent yet interlocking double wall assembly. My print has yet to make it out of the long and tedious printing process.

I developed the interlocking assembly from two offset walls the just by the next in section. Each of the two walls is made from an array of the same wall module. The funciton of the wall is to diffuse light to create an ambient light effect. Each of the extensions of the wall that cross on the inside of the wall from the light source is built with a scoop to draw in light and cast it on the surface facing into the low-light space. The scoop could also serve as a place for an imbedded light to serve the same funtion of showing light onto the surface facing into the space, during low light conditions.

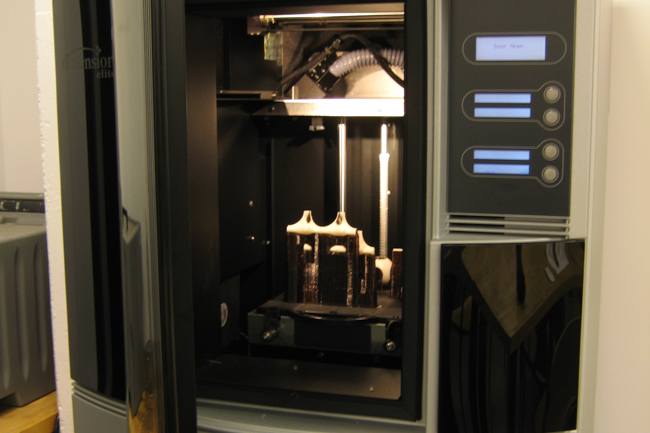

View of the wall module in the 3D printing machine. At 6 inches in width and height and 1 inch deep, it took over 24 hours to print.

Seen here within the build material, the wall was printed standing upright, allowing a preview of the undulation in the wall in real application . The build material (in glittering brown) is actually very beautiful and during construction one could see that it is comprised of a honeycomb pattern that is extruded, tapering upright.

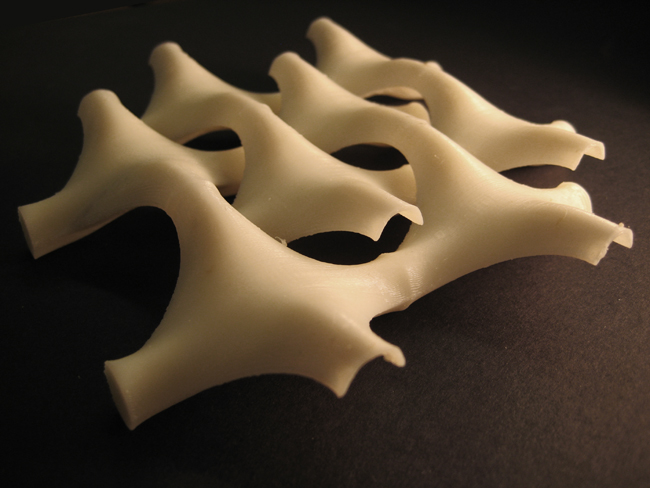

The sonic bath removed the build structure releasing its hold on the two indepedent wall assemblies, demonstrating further the interlocking nature of the full wall screen.